Our industrial and systems engineers are combining intelligent automation, direct printing, and real-time monitoring to improve every step of semiconductor manufacturing. That means faster prototyping, less waste, and more flexibility to support advanced technologies like chiplets, flexible electronics, and even electronics built in space.

They are also developing predictive models, anomaly detection systems, and digital twins to help manufacturers fine-tune performance and scale production with confidence.

By taking a practical, forward-looking innovation approach, we’re able to meet the semiconductor industry where it’s going, not just where it’s been.

Latest News

Wisconsin CHIPS joins SWAP Hub & ME Commons

Wisconsin CHIPS is pleased to announce its new membership to the Southwest Advanced Prototyping (SWAP) Hub led by Arizona State University. The SWAP Hub is one of eight that makes up the Microelectronics (ME) Commons, which was established to position the United States as a global leader in microelectronics research and enable domestic fabrication.

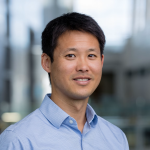

Kawasaki named a Moore Foundation Experimental Physics Investigator

Jason Kawasaki, an associate professor in materials science and engineering at the University of Wisconsin-Madison, has been named a 2025 Gordon and Betty Moore Foundation Experimental Physics Investigator. Selection to the program is a prestigious honor …

2025 Nobel Prize Laureate John Martinis’s Connections to UW–Madison

Wisconsin CHIPS congratulates the 2025 laureates of The Nobel Prize in Physics—John Clarke, Michel H. Devoret, and John M. Martinis—for observation of quantum-mechanical tunneling in an electrical circuit based on superconductors! Excitingly, Martinis has connections to UW–Madison through shared research and his co-founded company Qolab.

- More News